Piston Sets for 4⁵⁄₈” flywheels. 9.25:1 compres-

sion with rings. .030 size.

VT No. 11-0479

10-1091 23906-78G 1984-90 80”

1-Features replaceable pinion and sprocket shafts and narrow sprocket

side flywheel

2 Require use of 1987-up type pinon shaft bearing and retaining ring.

3-One piece type flywheel with non-removable shafts.

assembled and trued with shafts. VT No. 10-1091 requires the

use of 1987-up type Pinion Shaft Bearing assembly and VT No.

12-0967 late bearing retainer.

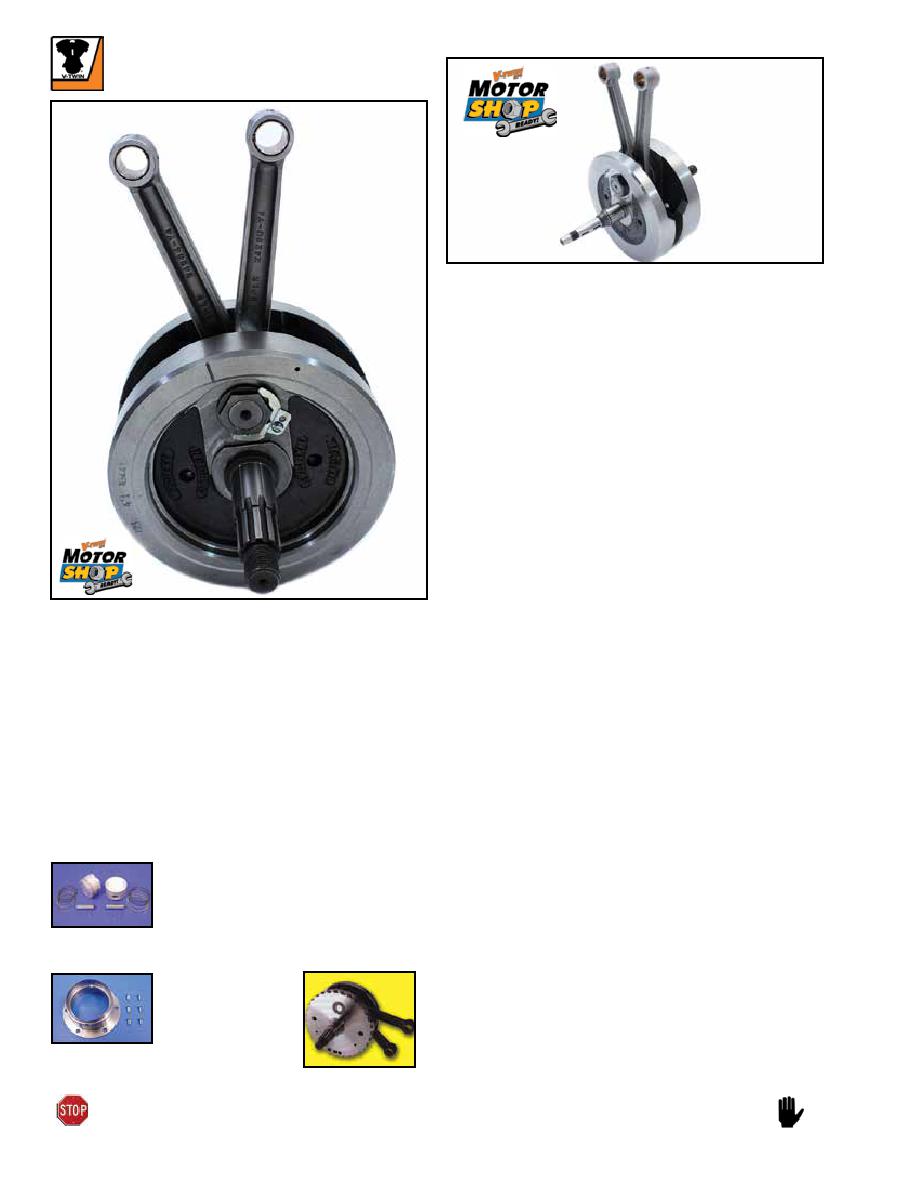

Twin Cam models. Feature 1.500 crank pin and replaceable race

bearing. Fits all models with non-balancer Twin Cam engines.

Pistons not included.

VT No.

10-1871 Brass Plug

will convert 2003-17

Twin Cam models from

a roller bearing to a

Timken tapered bearing.

Bearing sold separately.

VT No. 10-0856

note on for important information regarding emission control regulatory compliance and warranty information.

Flywheel that are out of round or scissored can be repaired. The new fly-

wheels on the 1999-up Big Twin are pressed together, but no match for our

V-Twin Motor Shop. We will press apart and disassemble this style wheel

assembly, inspect shafts, and crank pin components. V-Twin Motor Shop

will rebuild your Twin Cam flywheel assembly to OEM specification using

new bearings, crank pin and solid plugs, then balance and true. We can

also weld the pin and plugs, if requested, at the flywheel and crank pin inter-

face, for rigid power. We stock the bearings, cages and oversize crank pins

to provide you with the components at hand when your flywheel arrives. We

will hone the rods to allow the oversize pin to be fitted as required. Flywheel

set will be trued and balanced. The final assembly and press is complete in

our dedicated TC-88 flywheel fixture assembly.

If required, new connecting rods can be installed with customer’s authoriza-

tion. We balance the wheels for the new parts and stock piston weight. We

press the flywheel halved back together and true the bearing journals to

.001” or less. Truing the bearing journal eliminates engine vibration at cruise

speeds.

then tig weld the pin and plugs so flywheels won’t flex or scissor. This extra

step can help prevent future problems. The rebuilt flywheel is stronger than

stock OEM.

Dynamic Balancer. This service will require customer’s piston or purchase

of new piston kits from V-Twin.

also weld and repair all types of metal and aluminum parts like crank cases,

cylinders and heads.

wheels professionally rebuilt in V-Twin Motor Shop.

1-800-833-8946

VT No. Service

60-0249 Twin Cam Remanufacturing Service

60-0248 TC Remanufacturing with New Connecting Rod Set

60-0247 Crank Pin/Plug Welding Service

60-0123 High Speed Balancing with a flywheel remanufacturing service